Graphene Products: FAQ on Graphene Semiconductors

Research and development (R&D) of graphene products has intensified near-exponentially since the material was discovered in 2004. This has culminated in numerous new methods of generating the material including epitaxial growth, exfoliation, hydrothermal assembly, and nanotube slicing. The underlying reason for this plethora of production techniques is the widespread commercial appeal of monolayer materials, particularly

Photoluminescence and Monolayer Graphene

Photoluminescence (PL) is a fundamental optical process that defines how some materials emit light after absorbing electromagnetic radiation. It occurs routinely in the natural world, but experts in the field of photonics have endeavored to recreate and exploit this process artificially for decades. The genesis of two-dimensional (2D) structures like monolayer graphene has opened new

hBN Properties: Electronic, Mechanical, & Optical Potential

Hexagonal boron nitride (hBN) is a valuable polymorphic material that has been exploited by various market segments for decades, forming the basis of cosmetic products as early as 1940. Large-scale commercialization of hBN products lagged until the ‘90s when synthesis and production processes were optimized to meet growing global demand. The material was revolutionized yet

White Graphene: What is Single-Layer Hexagonal Boron Nitride?

Boron nitride is a synthetic refractory material that exists in several microstructural forms, which are typically characterized as either amorphous or crystalline. The primary form of interest in materials science sectors is hexagonal boron nitride (hBN), often referred to as white graphene. In powdered form, hexagonal boron nitride has found increasing use as a thermal

Grolltex Manufactures Smallest Graphene Strain Sensor Worldwide

Many materials scientists resist the hyperbole surrounding graphene. Yet the underlying optimism of the material is beginning to pay dividends as the commerciality of two-dimensional engineering continues to improve. This is most prevalent in the electronics market, where graphene has long been tipped to compete with silicon and other essential materials in sensor manufacturing. Graphene

Outlining the hBN Products from Grolltex

Hexagonal boron nitride (hBN) is a unique refractory material renowned for its outstanding thermomechanical, dielectric and transparency properties. Although analogous to all-carbon graphene, hBN products have a dielectric strength greater than refractory alumina (Al2O3) and a wide band gap in the region of 5.97 eV. This explains the material’s transparency when deposited in single- or

Outlining CVD of Graphene for Wafers

Since graphene flakes were first isolated via adhesive exfoliation in 2004, the material has arisen in several new permutations. Powders, ribbons, and graphene wafers have all been generated using novel techniques such as epitaxial growth in specialist reaction chambers. These techniques have rapidly eclipsed exfoliation in the race to commercialize graphene manufacturing due to the

Electronic Graphene Properties Explained

Initial theories suggested that isolating two-dimensional (2D) compounds was impossible, as thermal instability would cause the material’s molecular bonds to break apart. The successful isolation of graphene in 2004 disproved these theories and demonstrated the outstanding potential of two-dimensional material manufacturing. However, a quantitative explanation for these unique thermomechanical graphene properties initially proved elusive. Analysis

Exploring the History of Graphene Production

When graphene production was on the cusp of realization in 2004, it was considered a mechanical novelty with limited practical or commercial applications. Literature exploring the underlying theory of two-dimensional materials spans back to the mid-20th Century. Yet it was exclusively hypothetical and confined to academic fields until monolayer graphitic sheets were first exfoliated using

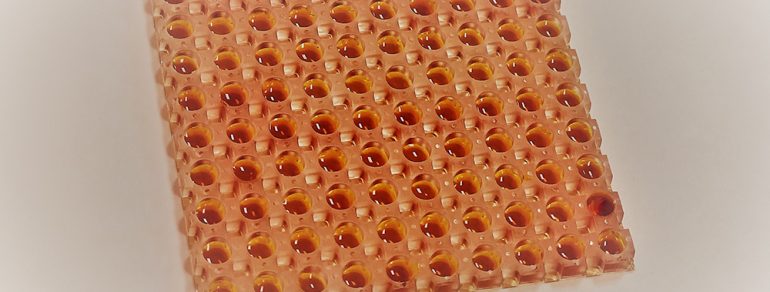

Grolltex Releases ‘Enhanced Performance Graphene’ for Electronic Devices

San Diego based graphene and 2D materials producer Grolltex has completed characterization and is releasing for commercial sale a configuration of large area, single layer graphene that exhibits dramatically improved ‘electron mobility’, which translates to better graphene performance. This ‘heterostructure’ contains a layer or layers of hexagonal Boron Nitride (or ‘hBN’) underneath graphene, enabling enhanced